Module manufacturing is decarbonizing rapidly

This trend is especially important for calculating "avoided CO₂ emissions" and "equivalent planted trees" indicators in photovoltaic simulations.

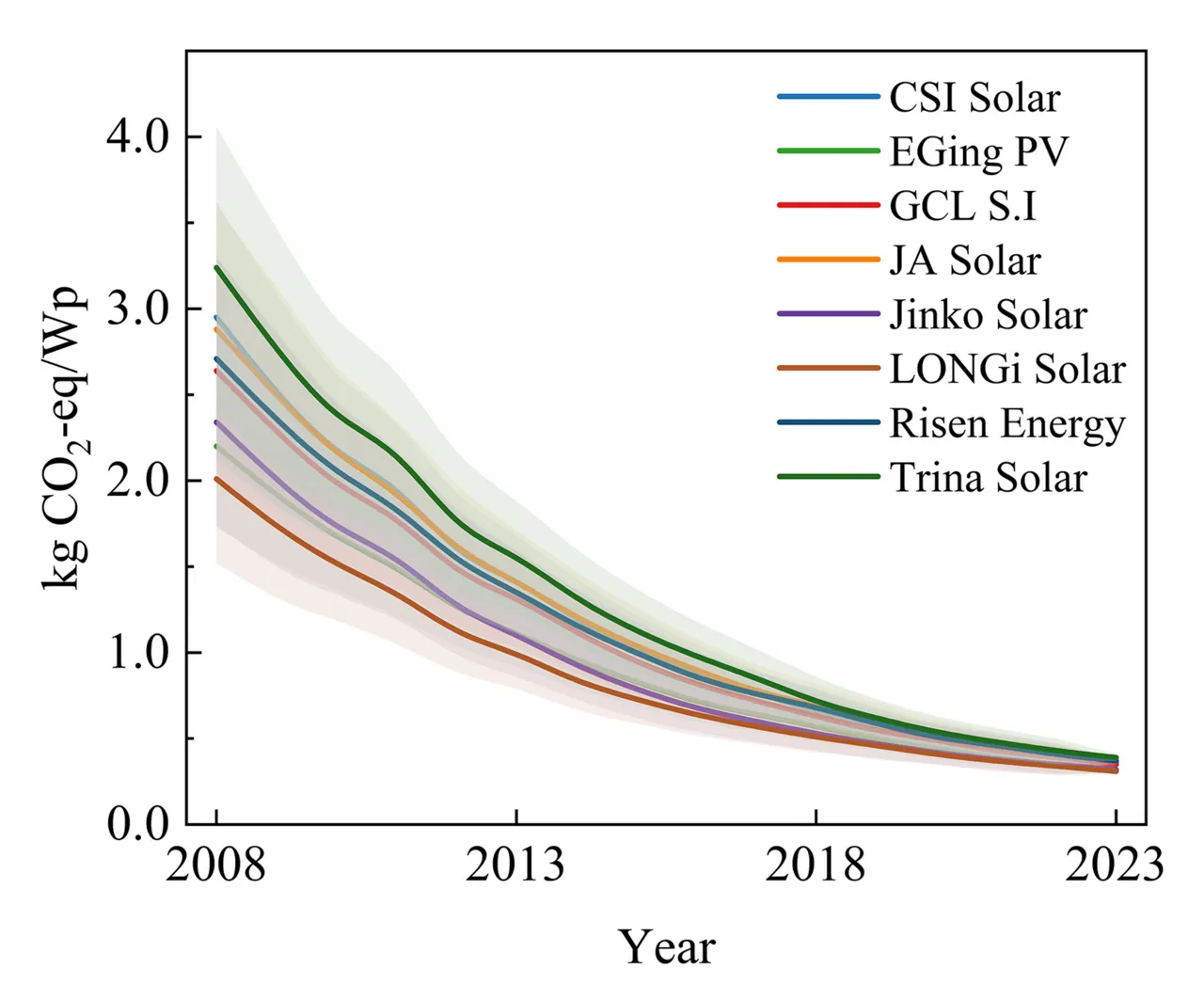

Recent research shows that the carbon footprint of monocrystalline PV module manufacturing in China declined from 2.01–3.24 kgCO₂eq/Wp to 0.31–0.39 kgCO₂eq/Wp between 2008 and 2023 (a nearly 90 % reduction per watt).

This has been possible thanks to several factors:

- ⚡ Decarbonization of electricity in major manufacturing regions.

- 🔥 Efficiency improvements in furnaces, ingot production, and wafer slicing.

- 🔪 Thinner wafers.

- 🔩 Lower aluminum frame emission intensity and better material use.

- 📈 Scale and learning effects across the supply chain.

These results, based on factory-level data from companies including Canadian, EGing, GCL, JA, Jinko, LONGi, Risen, and Trina, show how manufacturing improvements and the use of renewables can reduce life cycle emissions.