What is the best maintenance strategy?

In order to guarantee the performance and generation of a photovoltaic installation over time, it is essential to carry out various maintenance actions that can be classified as: preventive, corrective, and predictive.

🗓️ Preventive actions are based on establishing a schedule of interventions for the entire lifespan of the system. It forms the basis of traditional maintenance practices. During inspections, existing faults are detected and corrected by replacing defective components.

⚠️ Corrective actions are executed in response to serious equipment failures and system breakdowns. They are motivated by safety issues or significant income losses. These interventions are urgent and unplanned, making them more expensive and occurring only when losses are high enough to justify the logistics.

📈 Predictive actions analyze system monitoring data to identify signs of degradation, detect early minor faults, and prioritize maintenance activities.

But how do the different maintenance actions impact the performance, the number of interventions, and the components repaired during the installation's lifespan?

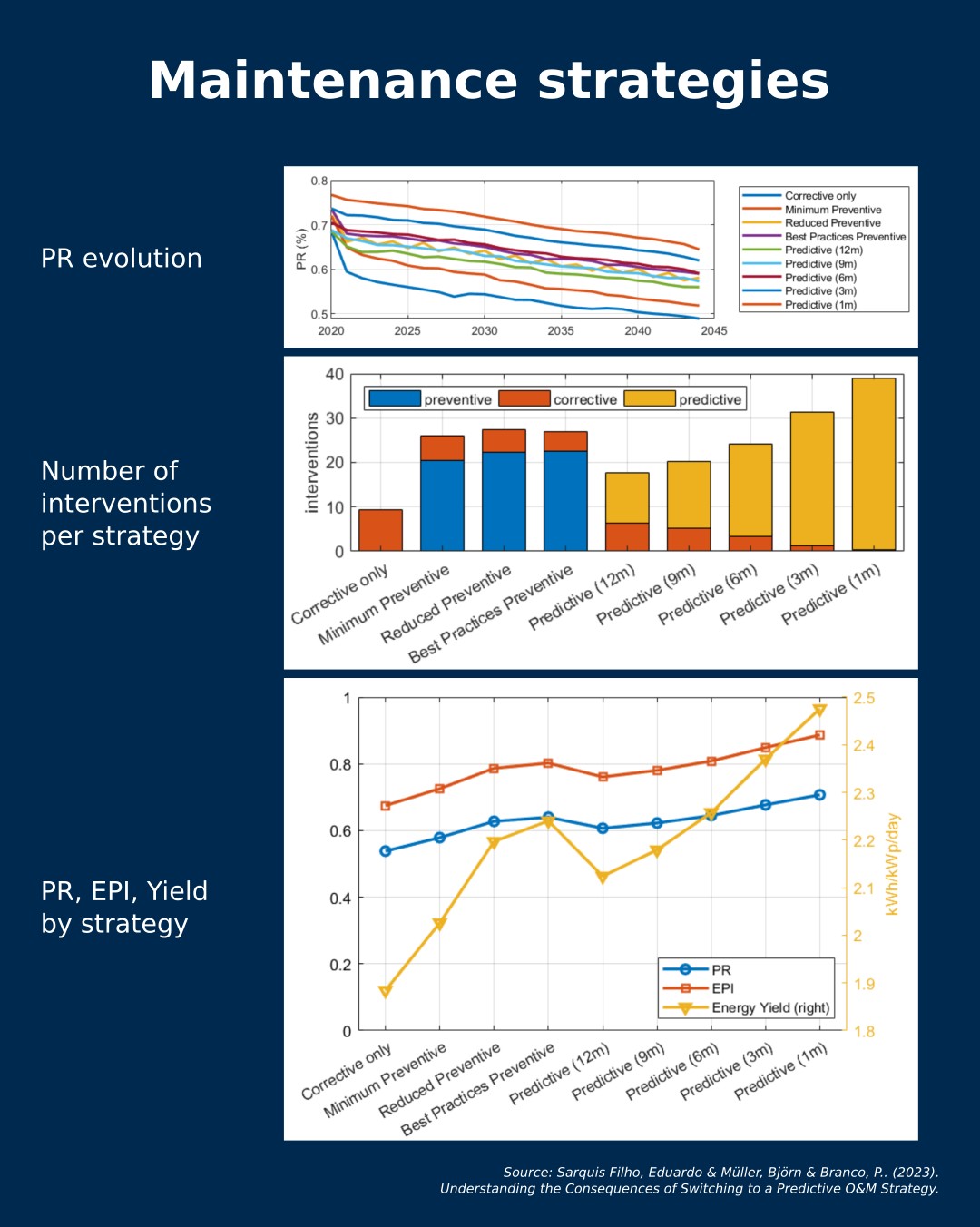

In the image, you can see the results of a study by IDMEC and Enmova GmbH evaluating various maintenance strategies that combine different actions.

The study results indicate that:

🌟 Current recommended best practices for preventive maintenance, including comprehensive annual inspections, maintain the system's performance at a high level (60+% average PR).

🌟 It is possible to maintain the average system performance by replacing preventive maintenance with a predictive maintenance strategy, with the advantage of reducing interventions and replaced components.

🌟 Benefits depend heavily on the response time (the time between detecting a fault and executing an intervention for maintenance). Short response times improve system performance but also increase the number of interventions.

🌟 Attempts to reduce and minimize maintenance actions must be undertaken with caution as they can significantly reduce system performance. With an only corrective or minimal preventive strategy, the average PR can fall below 60%.

Of course, to decide which is the best strategy, it is important to consider the project's characteristics: energy prices, monitoring costs, travel costs, costs of responding to corrective interventions, etc..