Are I-V curve tracers indispensable for detecting faults in the installation?

📊 If you need to audit an installation to validate the production of photovoltaic modules according to the manufacturer's specifications, it is essential to use a good I-V curve tracer. However, tracing these curves using inverters that implement the sweep functionality can be a valuable tool for monitoring and fault detection without the need for additional equipment.

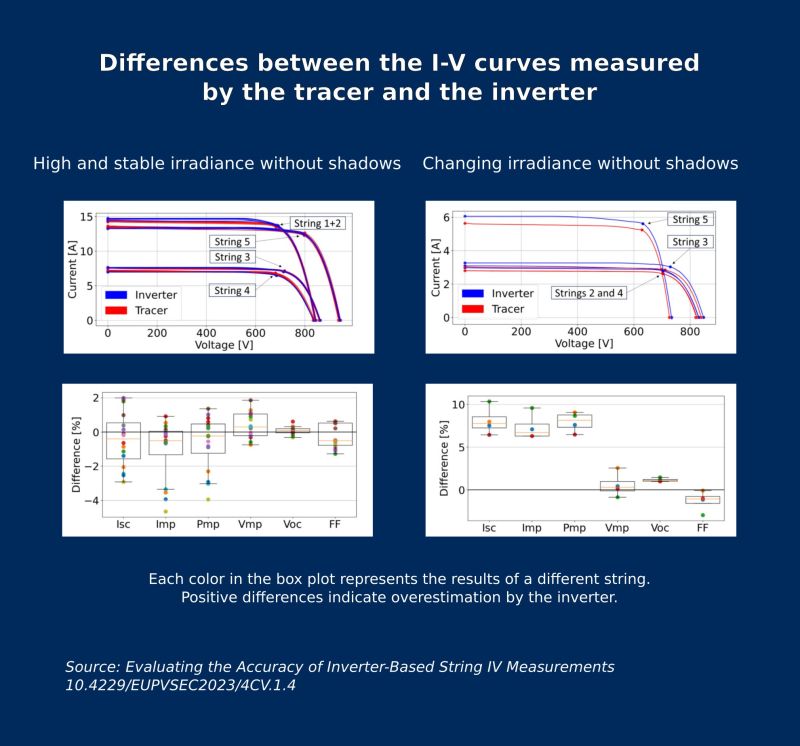

In a study conducted at DTU - Technical University of Denmark and presented at EU PVSEC 2023, the accuracy of these measurements has been evaluated under different conditions:

☀️ Under high and stable irradiance (GPOA > 650 W/m²), excellent agreement is observed between the I-V curves measured by the inverter and a commercial tracer, with an average Pmp error of 0.6 % and a maximum of 4 %.

☁️ In low irradiance conditions (GPOA < 400 W/m²), the error increases to an average of 2.7 % with a maximum of 6.7 %.

🌤️ In situations of changing irradiance caused by intermittent clouds, an average error of 8 % is observed in Isc, Imp, and Pmp. This error is attributed to the uncertainty in irradiance conditions during the measurement, as it cannot be guaranteed that the conditions are exactly the same during the sweeps.

🌳 In the presence of partial shading, inverter measurements are accurate when irradiance conditions are stable, and shading is minimal. However, in situations of severe shading, the inverter shows significant deviations, and under low irradiance conditions (GPOA < 220 W/m²), it is unable to produce I-V curves or identify inflection points caused by shading, although it can detect anomalies in the I-V curve of the string.

In conclusion, under conditions of high and stable irradiance, you can use inverters to reliably detect faults in the installation.

You can find the full original article at EU PVSEC website