How much do module mismatch losses affect your installations?

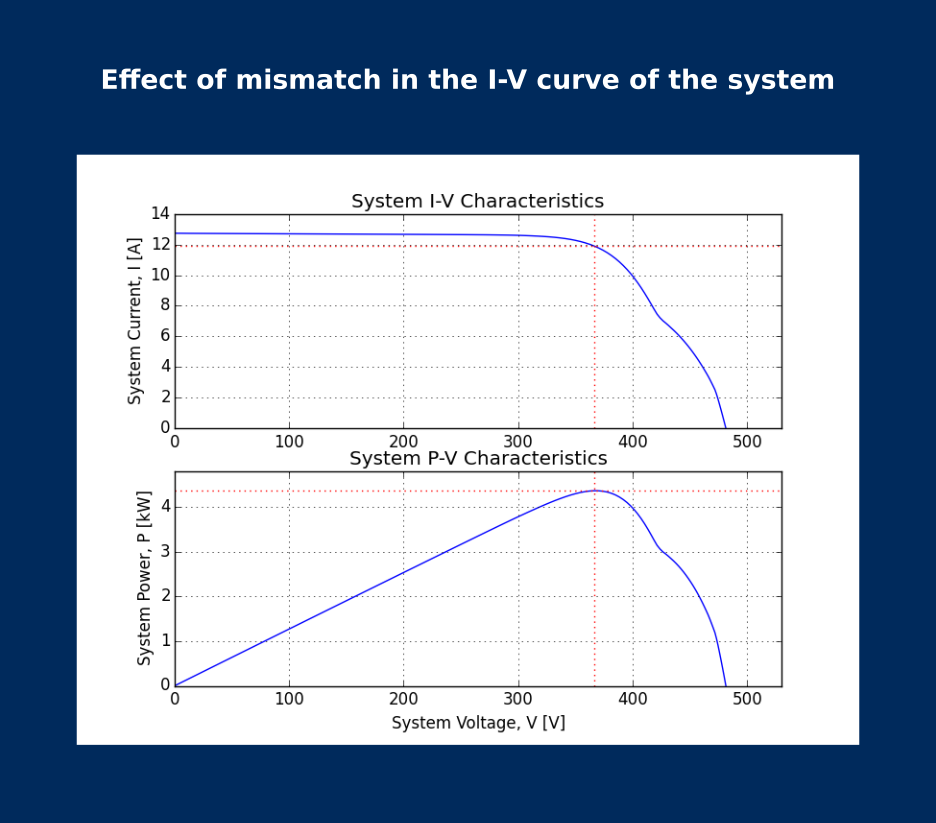

Module mismatch losses occur because within a series and/or parallel association of modules, there are differences in the electrical and performance characteristics of each module.

These differences cause the modules to operate at a point that is not their individual maximum power point, affecting the overall performance of the system in the form of losses. Additionally, if the differences are significant, they can cause overheating of cells in worse condition and severely damage the modules.

There are multiple causes that can contribute to this disparity, although the most common ones are:

❌ Each cell is unique, and within the same module, there is also cell mismatch. Manufacturers classify them based on performance to mitigate this effect, which is why you always find various power ratings (450, 455, 460 W, etc.) in the datasheet of a module.

❌ Within a specific model with a specific power rating, manufacturers always specify a dispersion (sometimes up to 5%), so a 450 W module will not always have that power but could have 453, 451, etc.

❌ After the initial exposure, Light-Induced Degradation (LID) losses can further increase the mismatch.

❌ Manufacturing processes are not perfect, and there may be flaws such as lower-quality soldering that affects some modules more than others.

❌ Microcracks and other damages that may occur during module transportation and handling during the installation process.

So, how does all of this affect your photovoltaic installation and power generation?

Although it's difficult to determine the exact value of mismatch losses, you can use the following values depending on the type of installation and modules you are using:

✅ 2% for most use cases with string inverters

✅ 1% if you use modules with a very tight power tolerance

✅ 0% if you use optimizers or microinverters